It’s an Edge Programmable Industrial Controller (EPIC), and the acronym says it all.

Simpler, less expensive, more secure

Meet the Future: Edge Programmable Industrial Controllers

A new kind of industrial controller simplifies and secures automation and IIoT projects, while reducing cost and complexity..

It’s an Edge Programmable Industrial Controller (EPIC)

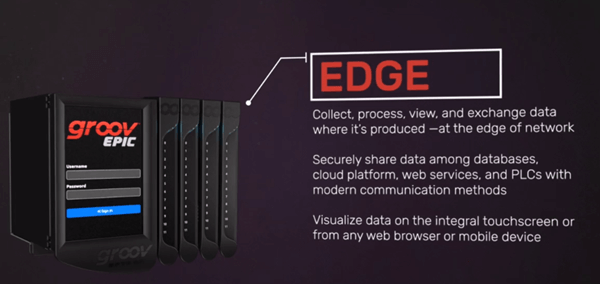

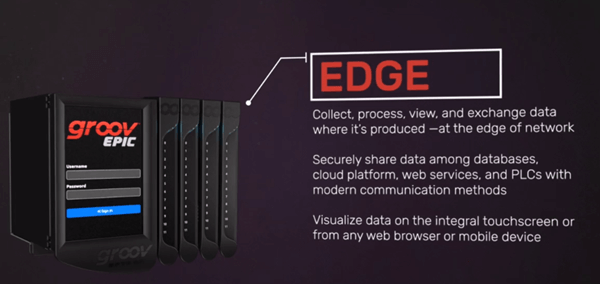

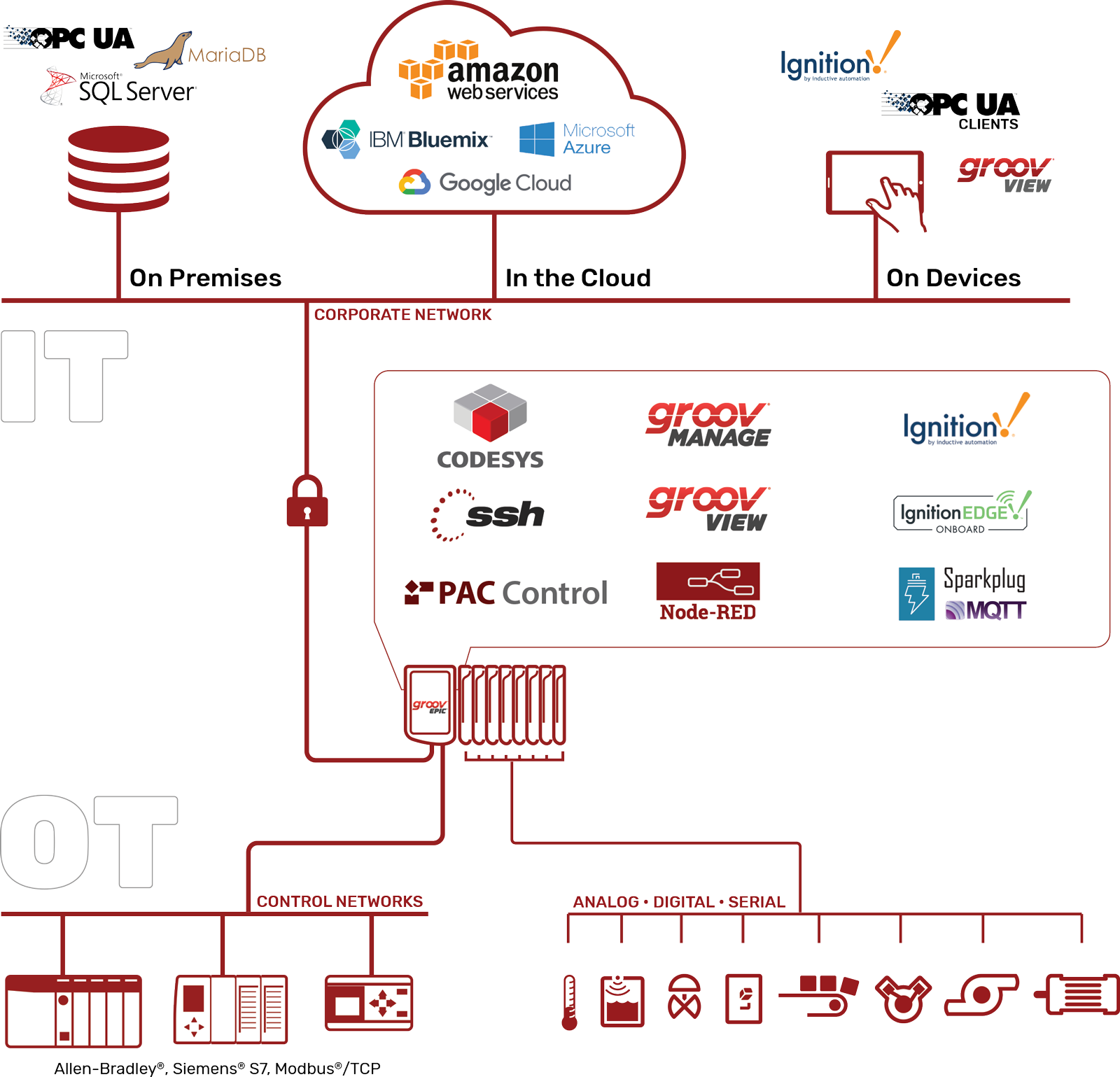

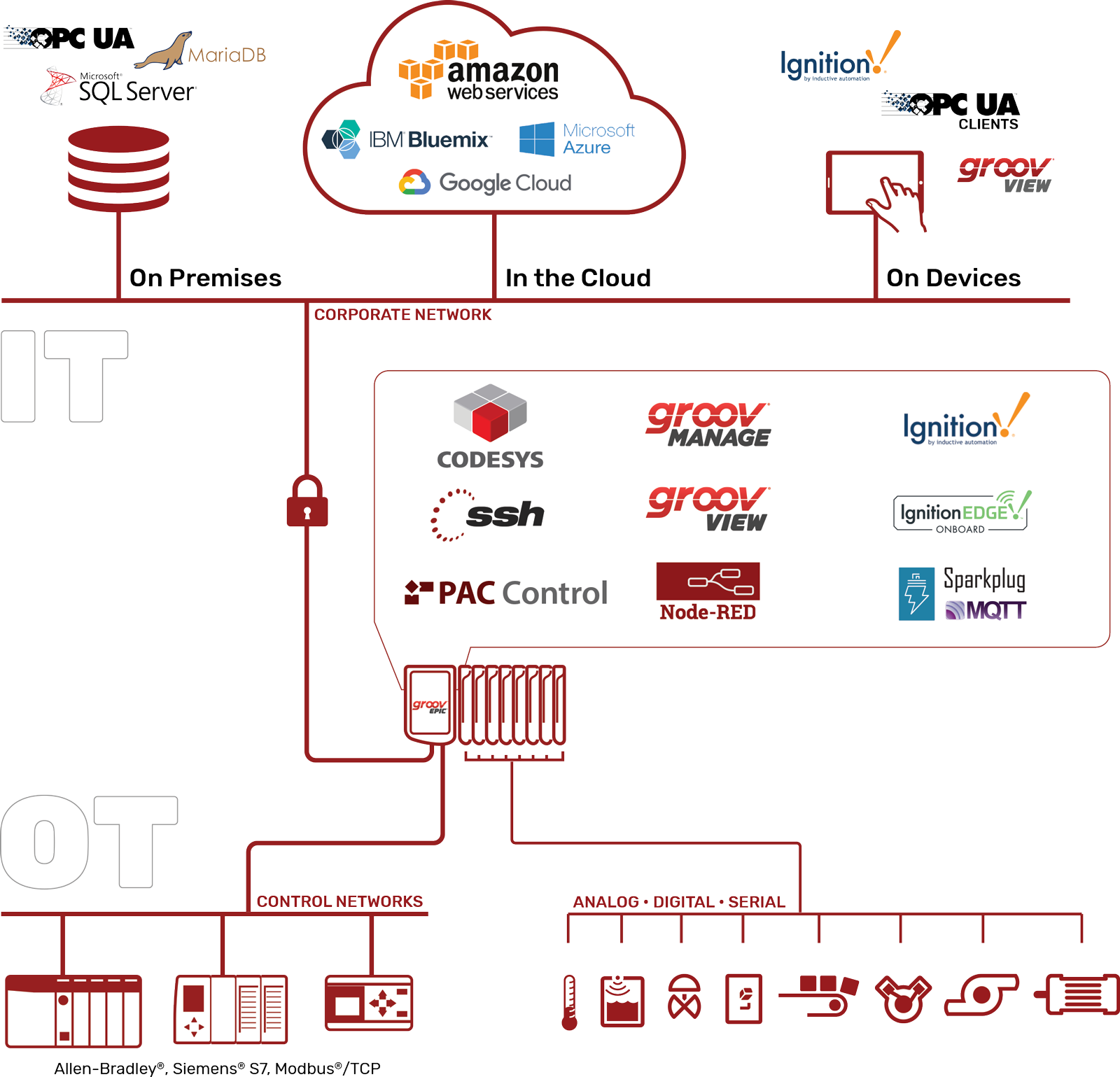

Edge

Now you can collect, process, view, and exchange data where it’s produced—at the edge of the network. When you work with data at the edge, you don’t have to worry about latency, and you have one single source of truth.

Securely share data among databases, cloud platforms, web services, PLC systems, and other systems and equipment, using open, modern communication standards. Built-in security features include configurable device firewall, VPN, encryption, user authentication, and more.

Connect with legacy PLCs and much more using Ignition Edge® Onboard or full Ignition from Inductive Automation®. Move data efficiently, decrease network load, and reduce IT reliance by using MQTT publish/subscribe communications.

Visualize data on the controller’s integral touchscreen, an external HDMI monitor, or from any web browser or mobile device

Programmable

Now you have new programming options:

- Program with the field-proven, flowchart-based, multi-chart control language PAC Control.

- Program with the field-proven, flowchart-based, multi-chart control language PAC Control.Use any IEC 61131-3 compliant language with the CODESYS Development System and CODESYS runtime.

- Exchange data using the visual, flow-based editor and runtime Node-RED, with its free pre-built nodes for databases, web services, and more.

- Run your own C, C++, Java, Python, or other custom-developed application on an open, Linux-based automation system, using secure shell access

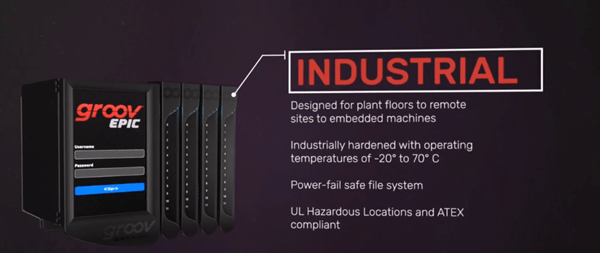

Industrial

From plant floors to remote sites, the edge demands industrially hardened equipment. Now you don’t have to worry about processing power in challenging locations.

groov EPIC has:

- Stainless steel processor and I/O chassis with a secure, screw-down design

- Industrial quad-core ARM processor and solid-state drive

- Industrial high-resolution color touchscreen display

- UL Hazardous Locations and Class 1 Div 2 approval

- Wide -20 to 70ºC temperature range

- ATEX compliance

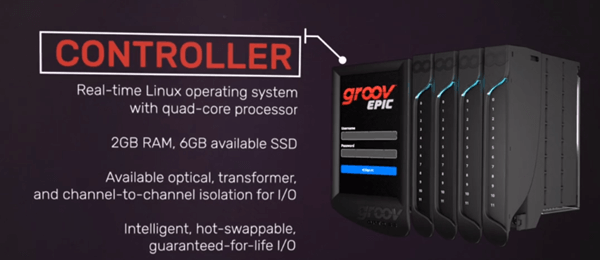

Controller

You can rely on real-time control and I/O from an automation manufacturer with 45+ years of experience. Opto 22’s worldwide reputation for quality was built on solid state relays and I/O, and all our experience is poured into the design of groov EPIC.

You’ll appreciate:

- Integral touch screen for local configuration, commissioning, and troubleshooting—no PC required

- Real-time, open-source Linux operating system

- Multi-tasking real-time control engine

- Dual independent Gigabit Ethernet network interfaces to help securely segment your control network from your business network

- HDMI port for optional local monitor

- USB ports for keyboard, mouse, Wi-Fi dongle, serial connections

- Intelligent, hot-swappable, guaranteed-for-life I/O

- Spring-clamp field wiring up to 14 AWG, with an integrated wireway and adjustable cover

- Multicolor LED for I/O module quality, plus channel indicators for discrete I/O

- Integrated power supply options

Now that’s EPIC!

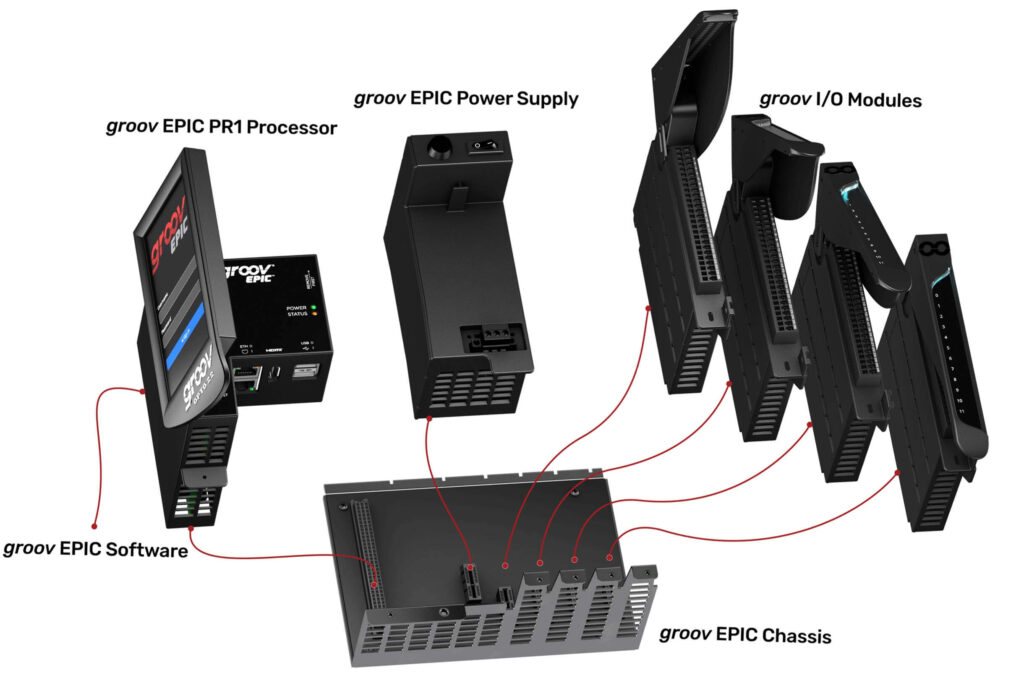

- The GRV-EPIC-PR1 controller with a Linux-based RTOS, gateway functions, and pre-loaded software

- Stainless steel chassis for 0, 4, 8, or 16 I/O modules

- Power supplies for AC, DC, and pass-through

- Guaranteed-for-life discrete and analog I/O modules with up to 24 channels per module, all configurable on the controller’s integrated hi-res touchscreen, or from your mobile device or any web browser

Security features built in, including dual independent network interfaces, firewalls, encryption, user accounts, certificate management, and more.

How groov EPIC features help you…

If you spec or buy systems:

- UL Hazardous Locations approved and ATEX compliant

- Wide -20 to 70 °C operating temperature range

- Stainless-steel chassis with 4, 8, or 16 I/O modules—or no I/O at all

- I/O module density of up to 24 channels per module

- Multi-featured analog input with voltage, current, and loop sourcing in single module

- Analog input resolution of 20 bits at 0.1% accuracy over span

- DC outputs with load switching at 0.4 A per channel @ 70 ºC

- AC outputs with load switching at 0.5 A per channel @ 70 ºC; blown-fuse detection

- AC/DC mechanical relay output at 5 A per channel @ 70 ºC

- Channel-to-channel isolation available

- Multiple power supply options including AC, DC, and pass-through

- Dual, independent Gigabit Ethernet network interfaces

- Fully compatible with the SNAP PAC System

- All products made in the U.S.A.

If you install, commission, or use systems in the field:

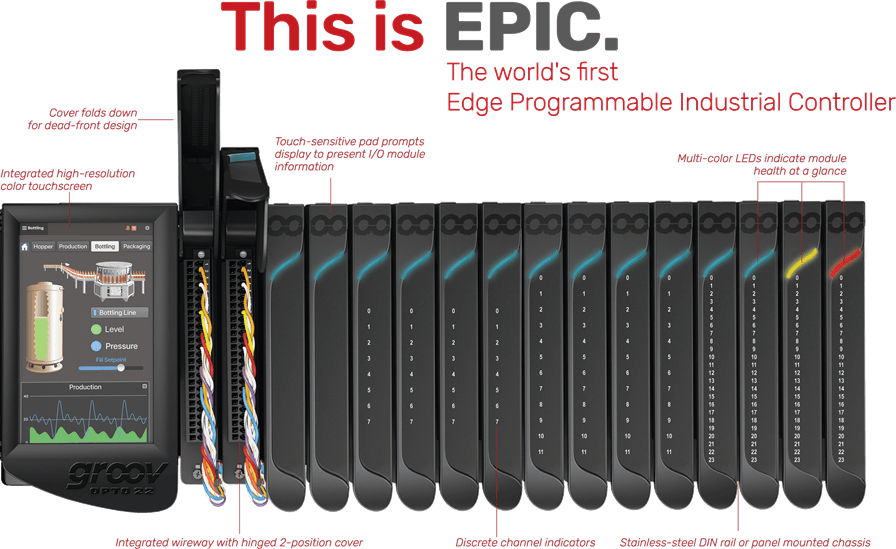

- Integrated high-resolution color touchscreen for commissioning and HMI

- No PC required for I/O and network configuration or troubleshooting

- Touch-sensitive pad on I/O modules for configuring and testing

- Viewable I/O module specs and wiring diagrams

- Stainless-steel DIN rail or panel mounted chassis

- Compact footprint with integrated power supply

- Spring-clamp terminal strip directly atop I/O module accommodating up to 14 AWG wire

- Integrated wireway with two-position swing-away cover

- Single module retention screw and strain relief tab built in

- LED indicators for module health at a glance, and for individual discrete channels

- Hot-swappable I/O

If you’re a developer:

- Securely shares data among databases, cloud services, PLC systems, and more

- Real-time, open-source Linux OS

- Programming choices: flowchart-based PAC Control with scripting orany IEC 61131-3 compliant language with the CODESYS® Development System

- Optional secure shell access (SSH) for your own custom-developed application

- groovView for building and securely viewing operator interfaces from any authorized mobile device or PC with a web browser—and from the EPIC controller’s touchscreen

- Open-source Node-RED for wiring together APIs, cloud applications, and databases with simple data flows, using pre-built nodes

- Ignition Edge (a product of Inductive Automation®) with OPC-UA drivers to Allen-Bradley®and Siemens® PLC systems

- MQTT transport protocol with Sparkplug payload for efficient data communications

- RESTful API to groovEPIC controller

If you’re an OEM:

- Remote configuration, troubleshooting, and system visualization from any web browser on any authorized device

- Integrated high-resolution color touchscreen with HDMI output for optional external monitor

- groovView HMI viewable on touchscreen, external monitor, and browser-based devices

- Dual, independent Gigabit Ethernet network interfaces

- Dual USB ports for serial communications or touchscreen monitors

- Real-time, open-source Linux OS running on an industrial quad-core ARM®processor

- 2 GB RAM, 6 GB user space on industrial solid-state drive

| Specification | GRV-EPIC-PR1 |

| Power requirements | 7.1 W typical, 9.1 W max. |

| Memory | 2 GB RAM 2 MB battery-backed RAM 6 GB user space |

| Backup battery for real-time clock | BR2032 |

| Screen size and resolution | 5 inches diagonal; 480 x 800 pixels |

| Ethernet Communication (wired) | Two independent 10/100/1000 Mbps RJ-45 connectors, each with a separate IP address (separate subnets) |

| USB | USB 2.0 (two ports; can be used to connect serial devices via a USB-to-serial converter with an FTDI chipset) |

| HDMI | Connector Type: A HDMI Specification: Version 1.4a Max. Resolution: 1920 x 1080 pixels at 60 Hz |

| Minimum PAC Project Version | 10.000 |

| Maximum Number of PAC Control Engine Charts | 64 |

| Torque, bottom hold-down screw | 3.5 in-lb (0.4 N-m) |

| Torque, top hold-down screw | 1.5 in-lb (0.17 N-m) |

| Operating temperature | -20 °C to +70 °C |

| Storage temperature | -40 °C to +85 °C |

| Humidity | 5–95% RH |

| Agency approvals and certifications | UL/cUL (Class 1 Div. 2), CE, ATEX (Category 3, Zone 2), RoHS, DFARS |

| Warranty | 30 months |

groov EPIC Software Architecture

Configure, commission, and troubleshoot your EPIC processor, I/O, and networking.

groov Manage is your central command to your groov EPIC system, helping you configure, troubleshoot, and commission your processor, I/O modules, and network interfaces.

- Configure networking and device firewall, including a VPN client

- Configure I/O (discrete, analog, and serial communication)

- Set up security and user accounts

- See I/O specs and wiring diagrams

- Check I/O status and values

- Troubleshoot the system

You can do all of this from the high-resolution color touchscreen built into the front of your groov EPIC processor, from a computer, or from a mobile device.

Program your groov EPIC with easy-to-use flowchart-based automation software with optional scripting.

Here’s another great option for programming groov EPIC: PAC Control, part of Opto 22’s PAC Project automation suite. Used for years in applications worldwide, PAC Control is a field-proven tool for developing control programs.

PAC Control uses a comprehensive, plain-English command set, which includes commands for analog process and digital sequential control, complex math, conditional branching, string handling, serial device control, PID loop control, and other complex functions. PAC Control is based on flowcharts, which offer a more intuitive alternative to ladder logic programming, and it also offers an optional advanced scripting language similar to C or Pascal. PAC Control includes subroutines, a graphical debugger, and a graphical PID control loop tuner.

The database of I/O points, variables, and other data elements you create in PAC Control becomes the single tagname database also used by PAC Display and groov View. Because this database is automatically available for HMI programming, you save significant development time.

Program your groov EPIC for industrial control and monitoring using any familiar IEC 61131-3 compliant language and the CODESYS Development System.

The IEC 61131-3 standard includes several languages, some of which you may already know. groov EPIC supports all IEC 61131-3 compliant languages, including:

- Function Block Diagram (FBD)

- Structured Text (ST)

- Sequential Function Charts (SFC)

- Ladder Diagram (LD)

Choose the language or languages that work best for your application.

Best of all, you can combine any of these languages for control with many of the other software tools available in groov EPIC—like Node-RED and Ignition or Ignition Edge—in order to do everything you need to on a single edge device.

You’ll use the PC-based CODESYS Development System V3 to create and compile IEC 61131-3 programs for download to a pre-installed CODESYS Runtime running on groov EPIC.

Build and view operator interfaces to monitor and manage your system from any device

From pumps and processes to production data to the weather, your world is full of things you need to control, view, or monitor.

With browser-based groov View, you can easily build an operator interface to see and interact with exactly what you need.

Authorized users can view your groov View HMI right there on the groov EPIC processor’s high-resolution color touchscreen, or on an HDMI monitor connected to the EPIC. They can also see the same HMI on their computers and mobile devices for remote monitoring and control.

Show data from sensors and automation systems, cloud applications, databases, web services, and more. Put the data and controls from different sources together in the way that makes sense for your application and your users.

Because you develop the interface yourself, your HMI includes only what you need—and everything you need.

- Start small.It’s easy to add another indicator or control if you find you want it.

- Keep it simple.If your interface is used on computers or web-enabled TVs and on phones, choose which gadgets to show on each.

- Include what’s important.Mix data and controls from any manufacturer or software maker on the same page, as needed.

- Give your authorized users access only to screens they should see. An operator may need to control part of a process, while a manager may only need production data.

groov View Compatibility

- Computers: You can build and view your groov View interface on any Microsoft Windows, Mac, or Linux computer with a web browser.

- Phones and Tablets:groov View works on any modern smartphone and any tablet with a web browser. Minimum operating system for Android, 4.0.1 (Ice Cream Sandwich); for iOS, 6.1; for Surface, Windows 8.

Suddenly, visualizing data is simple.

Extend the Ignition Platform to the edge of your network and connect popular PLC systems.

Two products from Inductive Automation® are available in groov EPIC: full Ignition or Ignition Edge®. Both give you two key connectivity pieces for your IIoT applications, OPC UA and MQTT with Sparkplug or string payload.

Full Ignition also adds external access to the OPC-UA server, scripting, database support, and a wide array of Ignition modules.

OPC UA

Available with Ignition and Ignition Edge in groov EPIC are an internal OPC-UA server and drivers for some of the most popular automation PLCs and devices: Allen-Bradley®, Siemens®, and Modbus®, as well as Opto 22 groov EPICs and SNAP PACs. With full Ignition, you can also access the server from external sources.

That means you do not have to buy, configure, and maintain an industrial PC in order to view and act on data from these systems. Because groov EPIC is built for industrial use, you can place it where you need it—in harsh environments or remote locations—and have the tools you need right there.

The following OPC-UA drivers are included:

- Allen-Bradley PLCs:

- Logix

- SLC

- PLC-5®

- MicroLogix™

- Siemens PLCs:

- S7-300

- S7-400

- S7-1200

- S7-1500

- Modbus/TCP devices

- Devices that support Modbus RTU over TCP

- Other drivers you have purchased

MQTT

Also available with Ignition and Ignition Edge is an MQTT Transmission module. MQTT (Message Queue Telemetry Transport) is a publish-subscribe (pub-sub) protocol that’s suited to many IIoT applications because of its architecture.

With MQTT in groov EPIC, you can use a strings payload or the Sparkplug payload specification. Sparkplug defines the messages that move over MQTT and gives you a way to make sure that data from remote devices and applications is current and valid.

With both OPC UA and MQTT in groov EPIC, you can move data to and from A-B, Siemens, Modbus, and Opto 22 systems in a non-intrusive way, without requiring an industrial PC, additional firewalls, or expensive network connections.

When you run Ignition on the groov EPIC, you can avoid the expense and maintenance of a PC at the edge.

Improve communications efficiency and reduce reliance on IT.

Included with Ignition Edge in groov EPIC is an MQTT Transmission module. MQTT (Message Queue Telemetry Transport) is a publish-subscribe (pub-sub) protocol that’s suited to many IIoT applications because of its architecture.

In a pub-sub architecture, a central source, called a broker, handles all data. MQTT clients can publish data to the broker or subscribe to get data from it (or both). Clients who publish data send it only when the data changes (report by exception). Clients who subscribe to data automatically receive it from the broker only when it changes.

Contrast this with a request-response architecture. There the client and server must be connected, because the client requests data directly from the server. The client doesn’t know when the data changes, so it must request it at regular intervals.

MQTT pub-sub offers three main advantages over request-response for IIoT applications:

- Network traffic is reduced overall, because data is published and sent only when it changes, rather than at regular intervals.

- Because the broker is a central source for data, servers don’t have to strain to serve multiple clients. And even remote devices with irregular connections or low bandwidth can publish or subscribe to data.

- For data publishers, there’s another important advantage: data is published using an outbound connection. Most firewalls block inbound traffic (for example, an external client requesting data from an internal server), but they allow outbound connections.

What does an outbound connection mean? It means that the device initiates the connection. Once initiated, data can travel in both directions. For example, whether a groov EPIC is publishing or subscribing to data, the EPIC initiates the connection. That’s an outbound connection, which the firewall would allow. Once the connection is made, data can travel bidirectionally.

MQTT Transmission with either a Strings payload or Sparkplug-B payload, available through both groov EPIC and the groov Edge Appliance, offers advantages for both on-premises and remote data communication.

groov EPIC systems in industrial areas connect to sensors and actuators through their own I/O and through other PACs, PLCs, and RTUs, and publish and subscribe to data through the MQTT broker.

At the main site, Ignition Edge and the groov Edge Appliance also publish and subscribe data through the broker, while providing database connectivity and system visualization.

MQTT Advantages

- Designed for industrial systems

- Device-originating communications

- Centralized security management at broker

- Data reported by exception. on change only

- Lightweight data communications

- Fewer communication links

- Much less traffic on network

- Ideal for intermittent connections

- Broker can be located onsite or offsite

- No need for VPNs or open firewall ports

- Less reliance on IT departments

Build simple flows to move data to and from databases, cloud applications, and APIs.

Included in groov EPIC is Node-RED, an open-source software program you can use to wire together devices, databases, cloud applications, and APIs (application program interfaces) with simple logic flows.

Many people use Node-RED for Internet of Things (IoT) applications. Node-RED provides engineers with an easy way to connect edge computing systems, such as industrial automation controllers, to cloud services such as Amazon Web Services™ (AWS) IoT, IBM Watson IoT™, and Microsoft® Azure®.

In Node-RED you connect prebuilt nodes (provided by device manufacturers or software developers) together to make a flow. The flow provides the logic to accomplish your goal. You can also add function nodes containing JavaScript.

Because Node-RED is a general-purpose programming environment, you have the freedom to create the flows you like using any nodes you choose. Opto 22 PAC Control nodes (for groov EPIC processors and SNAP PAC controllers), groov Data Store nodes, and a wide variety of other nodes are easy to install.

Build your own custom applications using languages you know, and run them on an open, Linux®-based automation system.

If you use C/C++, Python, Java, or other languages, you can use what you already know to build custom applications and run them on the groov EPIC processor through Secure Shell access (SSH).

The SSH protocol (Secure Shell) provides a secure remote login from one computer device to another. With strong authentication options (including passwords and public key authentication), plus strong encryption protection for communication security and integrity, SSH offers secure access for both users and automated processes.

What makes it possible for an automation controller to run applications built in standard languages? The EPIC processor runs an open-source Linux OS. Opto 22’s commitment to open, non-proprietary standards in automation gives you new options for control systems.

Purchase SSH for groov EPIC (part number GROOV-LIC-SHELL) and use it with toolchains and interpreters for Java, C/C++, Python, JavaScript/Node.js and more.

groov EPIC Features:

- grrov View 4.3a

- LDAP Support

- CORS Support

- PID Loops From groov Manage

- MQTT Enhancements

- Node-RED 1.1.3

- Ignition edge Option